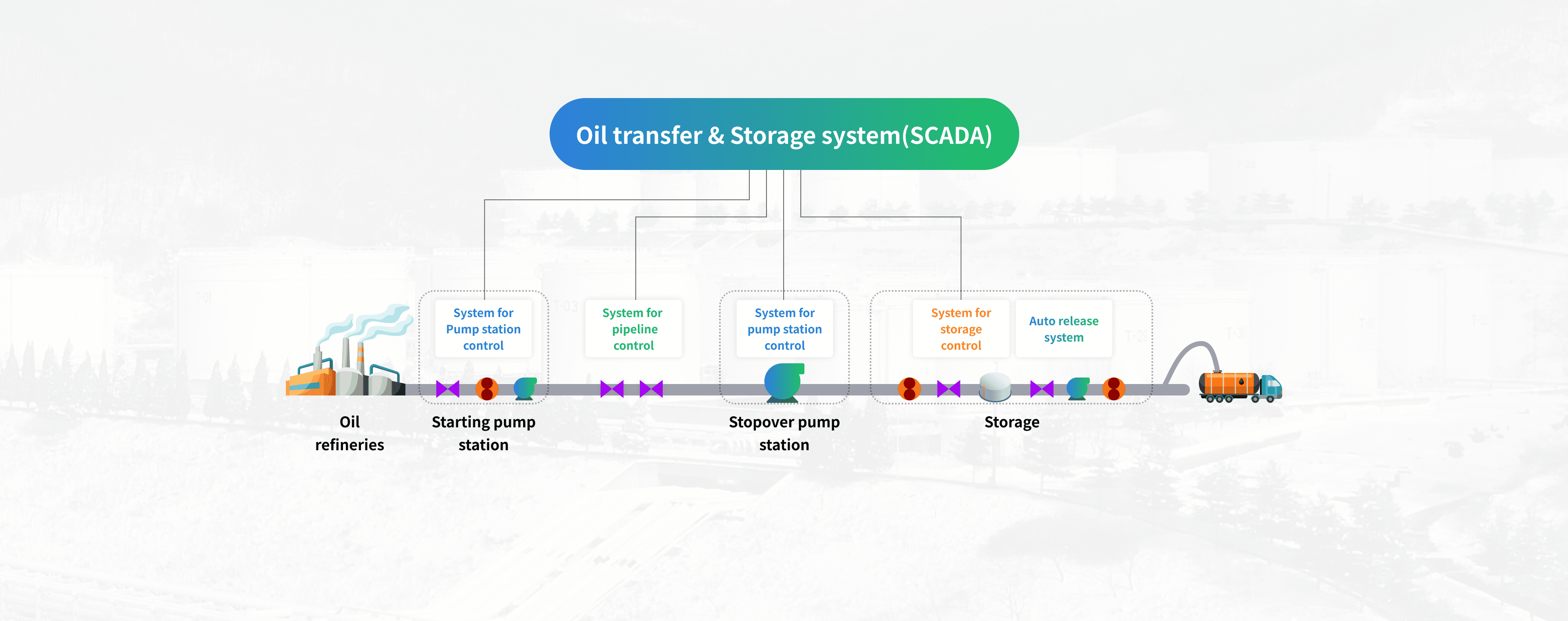

Petroleum pipeline operation process

- Submit an request of oil transfer

- Planning and Notification of oil transfer plan

- Acquisition of customer petroleum products for deliveries and distribution to terminal across the country timely transportation

- Remote operation through oil transfer and storage system (SCADA)

- Genuine quality control and quantitative inventory management

- Receive customer loading order and automatic loading

-

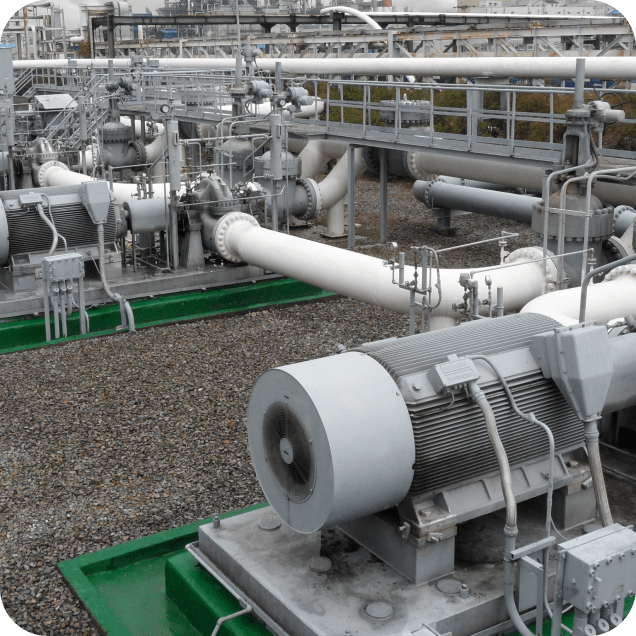

Transfer Pump

Transfer Pump

-

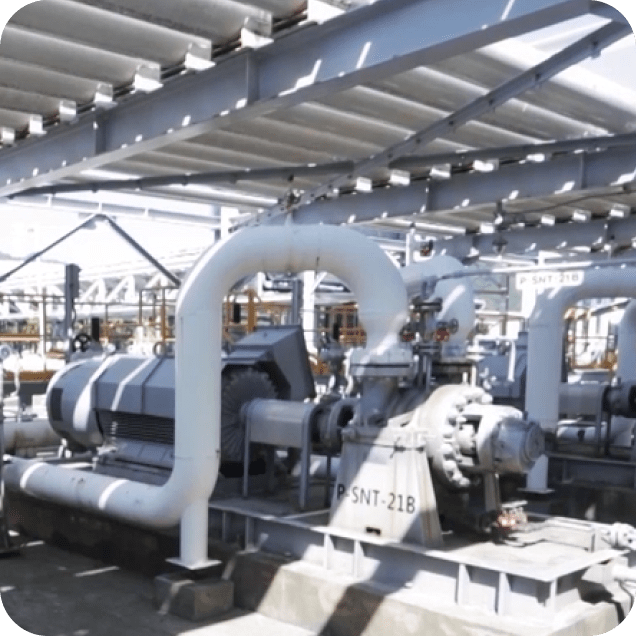

Oil pipeline

Oil pipeline

-

Process area

Process area

-

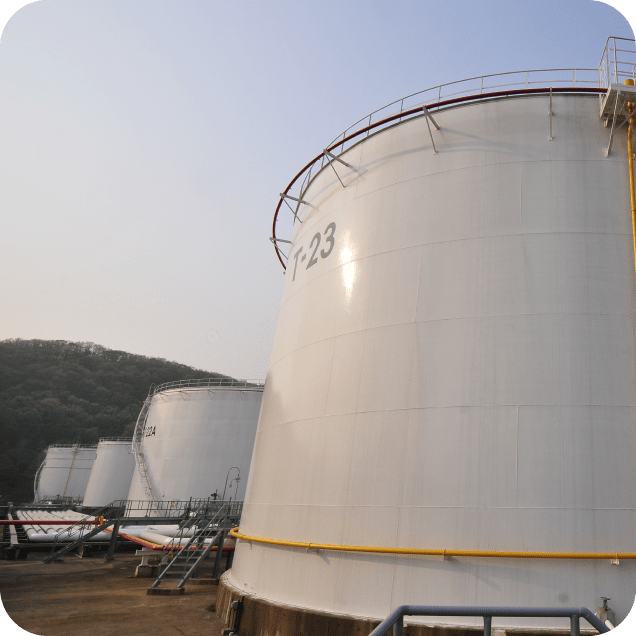

Storage tank

Storage tank

-

Truck loading facility

Truck loading facility

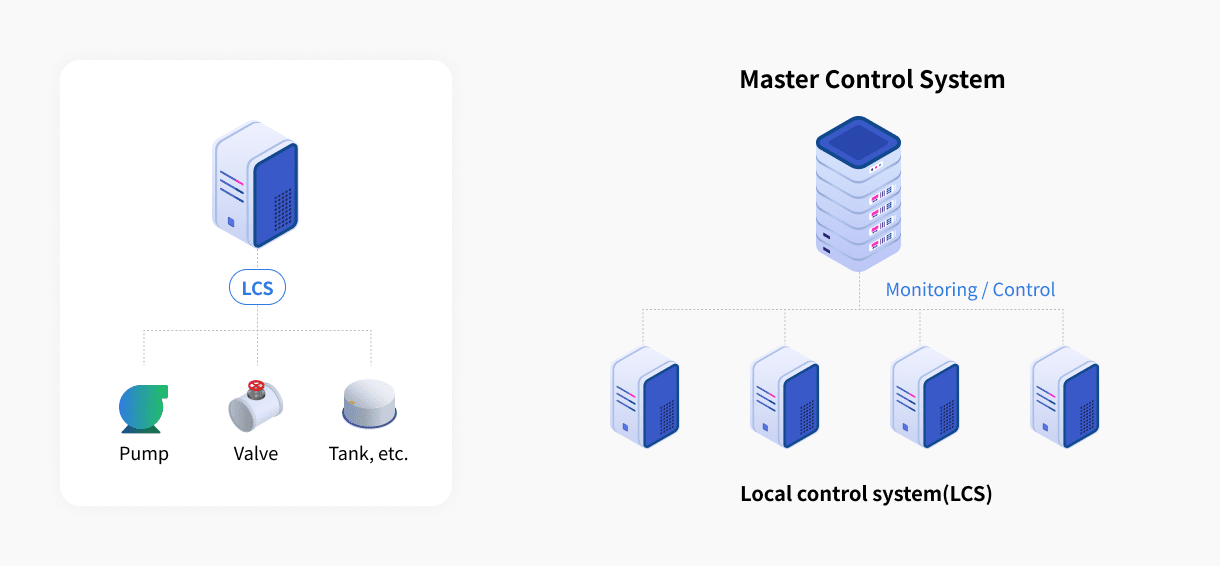

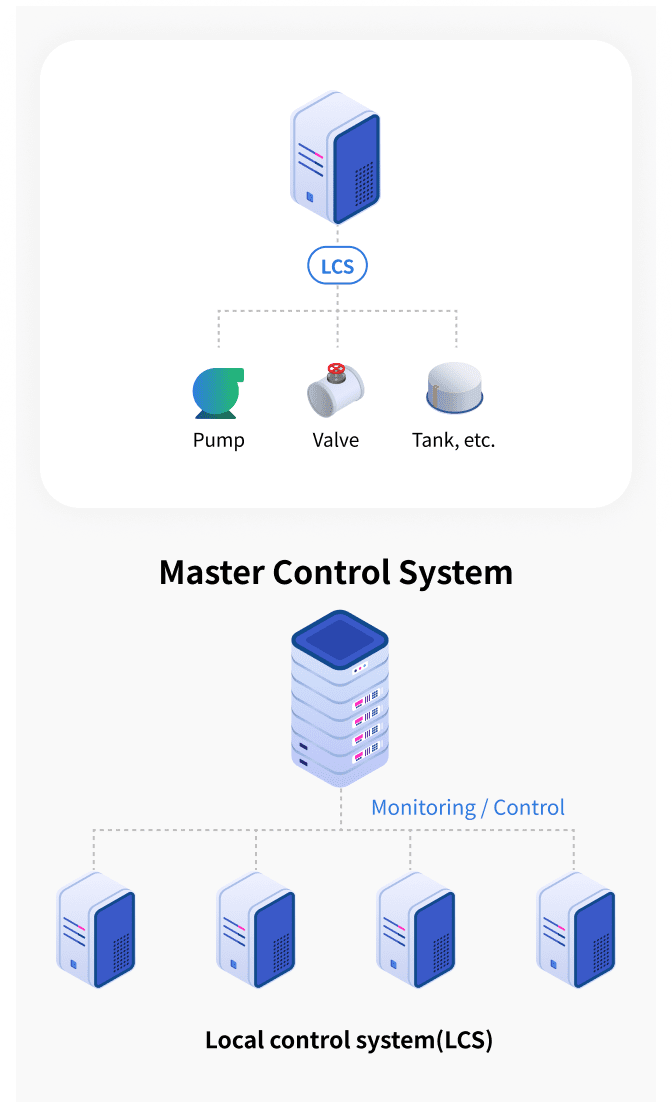

Major operation system

System configuration

Main function

Gathering and analysis of various information

The SCADA system collects and analyzes various information such as flow rate, pressure, temperature, and specific gravity of different oil products to ensure safe oil supply. The information analyzed in this way is used to perform tasks such as monitoring oil leaks in oil pipelines and oil transfer/receipt/storage facilities at each oil storage terminal and pumping station, and operating oil pumps and valves.

Real-time monitoring and control

DOPCO UniFM graphics displays the status of communication devices in remote locations on the screen, allowing operators to monitor and operate the facilities from control rooms located far from the sites.

DOPCO Terminal Automatic System (d-TAS)

(Entrance) Access approval → Vehicle entry

Bay/Loading Loading approval → Loading

Key features

- Application of loading safety interlock

- Prevention and management of safety rule violations and troubles

- Application of customer-oriented loading process and route (loading without stopping)

- Support for customer communication convenience functions (loading status board, etc.)

- Monitoring all loading system

- Remote monitoring and control of loading facilities

- High-speed communication, large data storage

- Operating computer and network duplexing

- Integrated systems available to all customers

- Unified system in all storages. Single control system